First things first, what actually is composting?

Composting typically refers to when matter decomposes via an aerobic process, meaning it relies on the presence of oxygen. When organic waste is composted, organisms naturally oxidise organic matter and convert it into nitrates, suplhur and sulphates, resulting in a nutrient-rich fertiliser. Whilst a small amount of C02 is produced as a waste product, aerobic composting is still a much cleaner alternative to sending waste to landfills, where methane is often produced as a byproduct.

What is compostable and biodegradable?

Why Compost?

Composting aims to not only treat organic waste with a natural method but also to produce an organic fertiliser which can then be used to improve soil conditions for horticulture and home use. Composting helps reduce the volume of municipal solid waste (MSW) disposed of in landfill sites and therefore helps to reduce methane emissions from landfills, lowering the overall carbon footprint of a product.

The common functions of Industrial composting and home composting

Industrial Composting vs. Home Composting

Many products are labelled ‘compostable’ these days but that does not necessarily mean they truly are compostable. Firstly, there are two different types of composting to consider - home and industrial composting and secondly, there are various standards that all compostable packaging has to meet before it can be officially certified.

Your home compostable bin vs the industrial composting site

- Home Composting

Usually carried out in a specially designed home composting bin, composting at home enables certain waste to be broken down over a period of months and results in a nutrient-rich soil. Conditions within a home composting bin will typically only reach a maximum temperature which is not adequate enough to break down many bioplastic products that are labeled compostable.

- Industrial Composting

Industrial composting is a multi-step composting process that optimises conditions by controlling temperature, oxygen levels, and inputs of water and air to rapidly biodegrade organic material and produce a toxic-free compost.

My packaging is compostable. How do I know how to dispose of it correctly?

Whilst both home and industrial composting are great solutions for food waste, many industrial facilities across the globe still do not accept packaging materials/bioplastics, which are often labeled as compostable. So whilst the world tries to find alternative solutions to single-use plastic bags, the use of compostable bioplastics is becoming more common but this isn't necessarily the positive news we've been hoping for.

For material to label itself as compostable, it needs to have the matching certifications to prove it can meet these requirements but it also needs to clearly state whether it is suitable for home composting or only industrial composting. For example, many compostable plastic cups are made from PLA which would not sufficiently break down in a home composting unit but would do so in an industrial facility.

Compostable Certificates and Their Requirements

Industrial Compostable and Home Compostable logos from around the world

Certification guidelines and requirements vary slightly depending on the specific requirement but to meet industrial composting requirements, products must generally meet the following:

- Minimum of 90% biodegradation of materials within 180 days in compost

- Minimum of 90% of materials should disintegrate into less than 2mm pieces in compost within 12 weeks

- No toxic effect of the resulting compost on plants and earthworms.

- Hazardous substances such as heavy metals should not be present above the maximum allowed levels

- Plastic materials should contain more than 50% organic materials.

Home compostable products are more of a recent development and as such, there are currently no international standards set. Some regions have set their own certifications though, such as Australia’s AS 5810, which many other regions are now basing their guidelines on and which states; a minimum of 90% biodegradation of materials must occur within 12 months, with no toxic effect to compost, plants and earthworms and materials should contain more than 50% organic material.

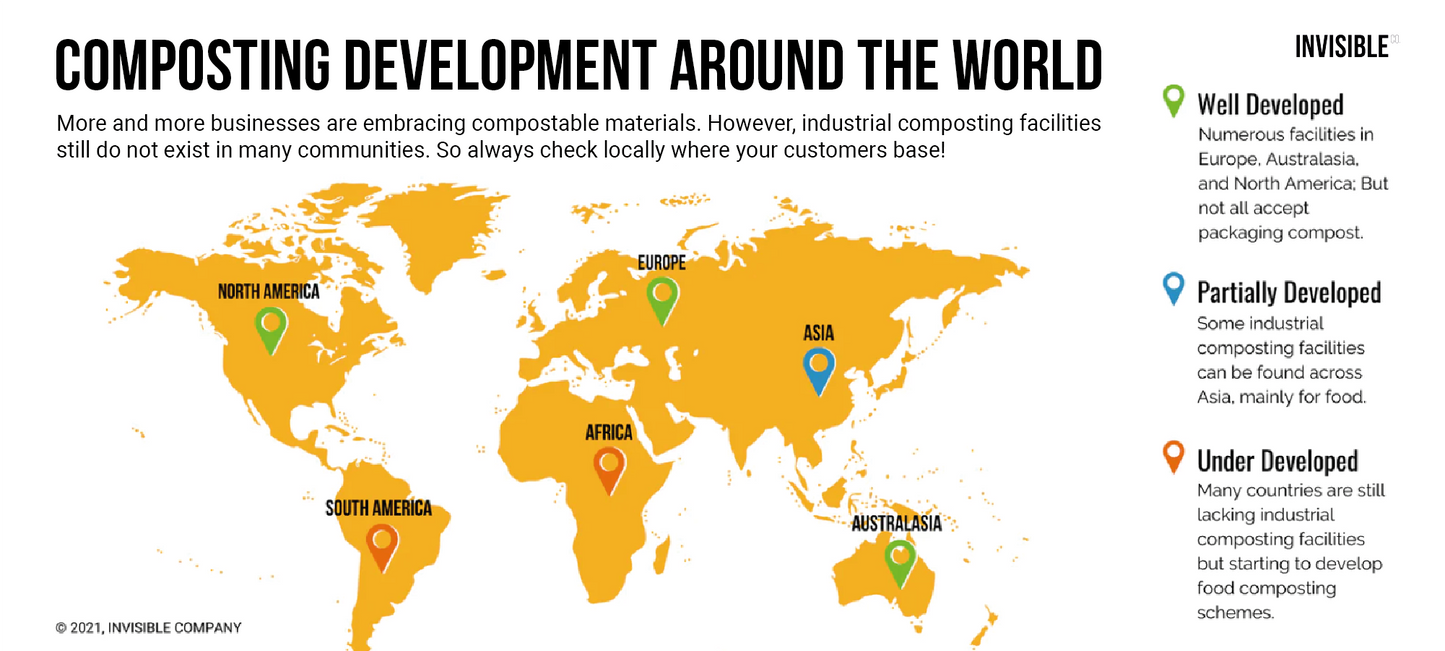

Composting practices around the world

There are several regions in the world that have embraced compostable materials and are successfully managing their disposal as intended but even in these countries, things are still not always straightforward.

In Australia, for example, many people do not realise that the recovery system for compostable packaging is massively under-developed. This means that businesses and individuals may not have access to collection services for compostable waste in their region in the first place, or collection might be possible but both consumers and recyclers may not be able to identify compostable vs recyclable materials and cross-contamination of waste streams then occurs.

Packaging should only be called compostable if it is indeed technically compostable and is certified to the standards of that country. There also needs to be a clear distinction between home compostable and industrial compostable materials, for both the consumer and the recycling services as a simple logo may not be sufficient.

Other Examples:

HONG KONG

- At present, there are two large-scale industrial composting facilities operating in HK, both of which only accept food waste. With food waste making up 30% of municipal solid waste deposited in HK landfills daily, developments are underway for additional facilities to open in the next few years but these are also set to accept food waste only as a priority.

- Home composting is not commonly practiced due to lack of space and public awareness

ASEAN

- Composting is practiced but in a limited manner. Some industrial facilities do exist but are only accepting food waste and on a relatively small scale by comparison to overseas counterparts.

- This further indicates gaps in recycling infrastructure, as well as gaps in technology usage for MSW volume reduction. ASEAN countries have limited experience of composting and incineration. (UN, 2017)

UK

- Whilst many businesses and consumers are rapidly moving away from single-use plastics, this is not necessarily aligning with the operational capacities of the waste and recycling industry. Over 170 composting industrial facilities exist but just how many of these accept packaging waste remains unclear.

- In a region such as the UK, where recycling systems are sophisticated and consumers are already well educated, it could be argued that recyclable bioplastics or traditional plastics may be more environmentally friendly when considering the whole life cycle of a packaging product.

US

- There are no shortages of industrial composting facilities across the US, and many of these have accepted packaging waste for a few years. The problem lies with the various State by State requirements as to exactly what can and can’t be accepted so things become very confusing for the consumer. Just across 30 States, it is estimated that there are over 500 different regulatory requirements.

That being said, regulations are evolving and more businesses are becoming increasingly willing to adapt to these challenges. More improvement is still needed though and this will need to involve collaboration between retailers, compostable packaging producers, and composting facilities to ensure that the infrastructure develops and becomes an affordable and viable option.

So... Should businesses use compostable materials?

If a material is truly certified compostable, of course, it has the potential to support the world's transition away from single-use materials to using more sustainable packaging methods but it needs to be used appropriately and there need to be adequate waste recovery systems in place.

Consumer education is the main factor that needs to be considered here when considering compostable products and it needs to be addressed with all stakeholders involved.

Brands and businesses first need to ensure their product meets the certification standards of the region they are selling in, such as ASTM D6400 in the United States, and EN 13432 in Europe. They should also be investigating whether there is a convenient recovery system in place and then educate their customers on how to correctly dispose of their product. Retailers and waste management councils should work together to work out an easily identifiable, highly visual system so that consumers do not become confused and do not accidentally send other ‘biodegradable’ materials which could contaminate composting streams.

Once the product is in the market, local councils and governments should provide education programmes for the correct way to identify and dispose of compostable materials and how these need to be separated for collection. For those consumers that are home composting, they also need to understand exactly which products are suitable for their system at home and which can only be collected for industrial composting.

Once collected, composting facilities need to have systems in place that ensure non-compostable packaging is removed and compostable materials are processed into a high quality, non toxic end product.

The future of composting

For compostable materials to be truly beneficial, the waste management infrastructure in that region needs to be compatible first. If there are no industrial composting facilities present, or if there are but they only accept food waste and not packaging, then sadly there is little benefit to use compostable materials as they will either contaminate recycling waste streams or end up in landfills where their compostability will be rendered useless.

#INVISIBLEBAG is certified industrially compostable according to the US Standard ASTM D6400 and the European Standard EN13432 which states that 90% or more of the material must be converted to carbon dioxide (CO2) by microorganisms within 180 days in ideal composting conditions. No harmful residues are left behind and the remaining share is converted into water and biomass.

To be a workable solution in all countries, regardless of whether there are sophisticated composting systems in use, #INVISIBLEBAG is also water soluble and proven to be biodegradable in landfill conditions by ASTM D5511 standards.

There is still room for improvement in the area of compostable packaging but it is a much more developed area than it was only a few years ago and it’s an area that shows great potential to be a highly successful waste management solution, so those initiatives looking to use it should still be supported and encouraged to grow further. To help educate yourself and your peers, you can try to research more about the facilities in your own region and whether compostable materials can be an option for you.

To find out more about #INVISIBLEBAG and the ways in which it can be used and disposed of, head to our what is #INVISIBLEBAG page!

...

You may also like: Going Plastic Free: How to get started with #Plasticfreejuly?

Sources:

- What's the problem with plant-based packaging (Recycling & Waste World, 2018)

- National compostable packaging strategy (Australian Packaging Covenant Organisation, 2021)

- What is the difference between home and industrial composting? (Biopak, 2020)

- Compostable food service ware may have challenges — but don't give up on it (Waste Dive, 2019)

- The Compostable Logo (Biodegradable Product Institute, 2020)

- Composting (Australasian Bioplastic Association, 2019)